F450 WASTE OIL FURNACE

SAFE, CLEAN AND RELIABLE

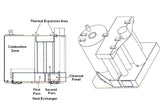

The INOV8 model F450 waste oil furnace is absolutely unique in the waste oil burning industry. The F450 resolves several challenges in burning waste crankcase oil in large BTU furnaces. 1) The heat exchanger is vertically oriented so ash sheds to the bottom between cleanings. This allows the heat transfer to be optimal between cleanings - to get the most BTU value from your oil. Most users report the cleaning frequency is once a heating season, and, 2)The heat exchanger has three passes in a counter-flow design. It is the most energy efficient heat exchanger design for oil type heat tested at 86%. It also allows cold air to enter the furnace without risk of damaging the steel, enabling its use for make-up air.

For installations that heat large facilities, the F450 cannot be beat in any category: energy efficiency, flexibility of fuels, durability. Paired with the model S200 waste oil burner in a downward firing configuration, the furnace consumes 3.78 gallons of oil per hour heating between 10,000 to 15,000 square feet. The furnace also has these additional features:

- A squirrel cage blower driven by a powerful heavy cycle-duty motor is standard and allows ducting to distribute hot air.

- Heavy duty construction (the furnace weighs 1,000 pounds) of high temperature aluminized steel, stainless steel, and ceramic.

- The finish has an industrial powder coat paint for easy maintenance, durability and great appearance.

For additional information, please go the the Furnace Page and/or click on the links that follow:

- Brochure

- Instructional Manual

- F450 Submittal CALL FOR CURRENT PRICING